【www.zhangdahai.com--其他范文】

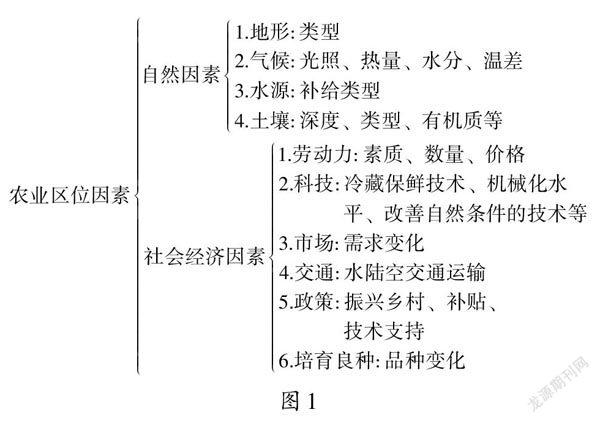

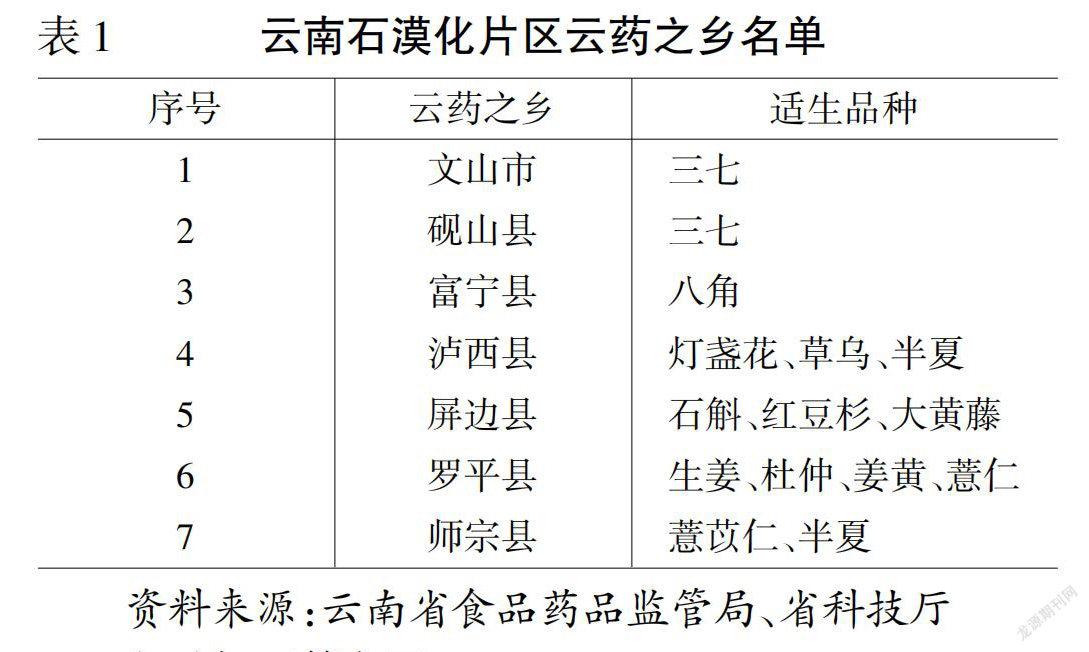

文/竺大文 涂佳煜

金逸瑞在杭州国家版本馆青瓷屏扇前。Jin Yirui poses for a photo in front of the celadon screens at the Hangzhou branch of the China National Archives of Publications and Culture.

踏入杭州国家版本馆南大门,扑面而来的是巨大的“梅子青”屏扇。那温润的绿仿佛倾泻而下,像远山,像碧水,拉开了一个宽银幕版的文润阁入口。

杭州国家版本馆一共采用了251樘屏扇,它由7万片纯手工烧制的青瓷片组成,全部来自浙江龙泉窑。在整个青瓷的工艺与艺术史上,我们很难找到如此大规模的应用。

从日常器皿化身宏大建筑,从生活场景移入传世工程。青瓷一脉,在江南绵延千年,在这个最新的文化地标处,完成了一次华丽转身。

日前,我们专程前往龙泉,对话龙泉青瓷非物质文化遗产传承人金逸瑞—他创建的南宋哥窑瓷业有限公司是3家青瓷屏扇生产企业之一,听他讲述制作中的灵感和辛苦,感悟文化里的传承与创新。

制作杭州国家版本馆的青瓷屏扇,用的是特制的新式窑炉。金逸瑞的公司共制作了3个窑炉,从去年4月起夜以继日地投入烧制,才成就了这万片青瓷。

我们在现场看到这些貌不惊人的窑炉,却想不到其中蕴藏着如此多的奥秘。

这一切要从金逸瑞参加的一次颇为神秘的会议开始。2020年7月,杭州来的团队在龙泉征召企业,说要做一个大工程,条件是能够制造30厘米×80厘米左右的大块青瓷板。

当地20余家重点生产厂家都去了。“当时,我们认为这是不可能的。”金逸瑞说。

瓷板对表面平整度的要求与日常瓷器天差地别。一位巧匠在陶轮旋转的离心力下能以双手塑造出圆滑的弧度,但一块平整无瑕的青瓷板,非机器切割往往难以达成。他们无法想象这么大的青瓷板会用在什么场合。

金逸瑞指着桌上一块书本大小的茶盘说:“之前,这样大小的瓷板都很难做。”

开会回来后,他还是琢磨开了。遥想南宋时期,龙泉窑一反越窑的深沉,以“胎薄如纸,釉厚如玉”的轻盈通透惊艳世人,达登峰造极之境。这与当时的工匠以黏度更大的石灰碱釉替代石灰釉,首创“多次素烧,多次施釉”的技术密不可分。

金逸瑞说:“一次创新,其实就是跨过了之前技术上的某个界限。”

没有任何捷径,他只能一遍遍烧制、摸索。版本馆的设计团队、工程专家也数次来到龙泉,共同商讨方案,给了金逸瑞莫大的信心。

由青瓷板切割制成的茶盘衍生品。金逸瑞/供图An accompanying item for a tea set cut from celadon. Photo credit: Jin Yirui.

历时半年,烧出的瓷板从15厘米×30厘米、20厘米×40厘米的小尺寸,逐渐扩大到当时窑炉所能容纳的最大尺寸30厘米×60厘米。

此时,起初的20多家企业在试验中一一退出,最终只剩下金逸瑞的龙泉市南宋哥窑瓷业有限公司、龙泉瓯江青瓷有限公司、龙泉市宝溪先明瓷厂3家进入最终的研发生产环节。

金逸瑞意识到,要进一步突破尺寸的限制,必须为青瓷板量身定制新的大型设备。新窑炉好不容易做出来,又带来了其他问题。在窑炉内部,20余层层间距约5厘米的隔板整齐叠放,全部装入青瓷板后,整个炉子增加约平时两倍的重量,带来承重隐患。金逸瑞不得不重新设计窑车轨道,用铁件二次加固底座。

瓷板间隔密集,冷却不够快怎么办?金逸瑞再次想出妙招,在窑炉侧面、正面各开出若干通气孔。

这一年多,金逸瑞把其他的订单都推掉了。当第一块烧制成功的青瓷屏扇出炉,他不禁轻呼了一声。

在这生生不息的千年窑火中,曾蕴含历代青瓷艺术家的多少创新之举,至今这窑火仍在跳跃不已。

青是山水之色。

龙泉地处群山环抱之间,瓯江水之源,山水的灵魂便附着于瓷胎之上。陶瓷考古学家朱伯谦记载:“龙泉窑开创于三国西晋,生产瓷器的历史长达1600年,是中国制瓷历史上最长的一个瓷窑。”

金逸瑞酷爱这一份青。后来,他知道了这些产品将用作国家工程,用作国家版本馆的主要构件,更感到一种冥冥中的必然。

代表“青瓷釉色与质地之顶峰”的梅子青,色如挂枝初梅,青翠碧绿,正应了杭州国家版本馆“文润阁”的“润”字。

然而,二次烧成的青瓷板经过切割修整,四面会露出白色的胚边,侧面看去不免破坏屏扇整体的色彩。为此,青瓷扇板除尺寸的突破外,还一改以往的两次烧成为三次烧成。

打破常规的第三次炉烧,就是为了让这一厘米宽的细边也能挂上精致的釉色。金逸瑞期望,即便在百年之后,每一片瓷板被拆下来,也都是一件传世的艺术品。

这份对青瓷的执念,深深地根植于20世纪50年代以来龙泉窑的复兴之中。

当年,在中央领导的支持下,沉睡的龙泉窑火被重新点燃。新成立的龙泉国营上垟瓷厂汇集了一批青瓷艺术的泰斗级人物,其中有国家级“非遗”龙泉青瓷传承人徐朝兴、中国工艺美术大师夏侯文等。

金逸瑞俯身检查青瓷板的平整度。胡春麟/摄Jin Yirui checks the smoothness of a celadon plate. Photo by Hu Chunlin.

金逸瑞一家也赶上这波浪潮。1955年,他的父亲才15岁就从温州到龙泉做青瓷。后来,生了兄弟姐妹6个,现在5个都在从事青瓷行业。

2009年,龙泉青瓷传统烧制技艺成为“人类非物质文化遗产”,而在两年之前,金逸瑞已经正式师从徐朝兴大师。青瓷艺术的接力棒传到了他这一代的手中。如今,金逸瑞和长兄金逸林、金逸荣3人均已是工艺美术大师,成为龙泉青瓷血脉延续的中坚力量。

这次的青瓷屏扇,多一次烧制,完工时间就将增加15小时。不仅如此,青瓷在第三次烧成时,挂釉极其困难,还非常容易开裂,“经常是一窑又一窑推进去,拉出来全都断成好几截。最终的成品率只有50%。”金逸瑞不无心痛地说。

这种不惜工本的做法,为的是细节之处的尽善尽美,为的是将他所热爱的青瓷艺术臻于极致。

版本馆尚在建造中期,金逸瑞来到杭州,看到了只安装了一半的屏扇,就把他激动坏了。目睹日夜触摸的瓷片、千番调制的色泽以如此宏大的形式铺陈开来,在国家级文化工程中被大面积运用,他的感动与骄傲之情无以言表。

他一遍遍地跟我们强调:“青瓷终于被作为主体得以运用,不再是装饰、附带、点缀,是一万平方米的主体啊!”

“瓷器里有最深的文化。”金逸瑞的这句话,道出了他传承青瓷制作技艺36年的经验,更道出了这次承接杭州国家版本馆工程的感悟。

试烧留下的近万件“废板”,金逸瑞舍不得丢。在他的工作室里,有各种切割下来的青瓷屏扇。他不时地摩挲它们,想象它们各种可能的形态。

南宋青瓷,插花瓶、饮茶杯、焚香炉,釉色纯净天然,所谓“绚烂至极,归于平淡”,是宋人生活美学的极致展现。

杭州国家版本馆,青瓷屏扇整体的大气铺陈,开如层峦叠翠,合如粼粼碧波。原来青瓷还可以传递这样一种正在进行时的文化自信。

大尺寸、三次烧成、大面积铺设,在金逸瑞看来,这是杭州国家版本馆青瓷屏扇的三项创举。这种对于龙泉青瓷的大胆运用,在将其艺术造诣推向高峰的同时,也为龙泉青瓷未来的发展打开了一扇门。

金逸瑞会花许多时间去耐心地沉入想象,就像他一直以来做的那样。

在工作室的展厅里,摆放着一只莲花形状的哥窑盘,盛放的大莲花中心,一朵小莲花悄然舒展,金逸瑞将作品起名为《母子莲》。

“母亲去世后,我们经常会想到她。”金逸瑞解释道,“因此想做一件瓷,作为寄托我对母亲思念的载体”。龙泉青瓷中,莲花元素并不少见,如何借传统元素抒发个人情感,金逸瑞寻觅灵感整整三年,最终呈现出母子连心的寓意,动人心扉。

现在,金逸瑞和他的同行,愿意花更多的时间去寻觅龙泉青瓷中古今相通的人文意蕴,触摸古典青瓷中现实的温度。

金逸瑞制作青瓷器。金逸瑞/供图Jin Yirui works on a piece of celadon ware. Photo credit: Jin Yirui.

“说起来它们全身都可以用,只是怎么用的问题,情感是否正好跟器物配得起来。”金逸瑞拿起一块屏扇说,“传统的东西是非常经典的,但每一辈的人感情总有些不一样”。

他说,如果这种形式的青瓷能被大家接受的话,龙泉青瓷整个产业就会被带动起来。这是一个“上不封顶的全新的空间、独立的市场”。

金逸瑞做各种尝试,把屏扇切割成不同形状的茶盘、壶承、杯托,他在釉上手绘兰花的图案,仿佛一张壁画。他珍藏着一块烧制中意外剥落的完整釉面,说这是绝版,但没想好做什么,或许这是一种无用之用。

在这位工艺大师的身上,闪烁着发明家的创造热情。他甚至烧出独具一格的朱红色瓷板,反问道:谁说龙泉瓷一定是青色?工作室的墙边靠着一块高度与人比肩的巨型青瓷板,是杭州国家版本馆瓷板面积的四倍多,是他趁热打铁、挑战极限的得意之作。

曾几何时,龙泉青瓷以“雪拉同”的美名流传世界,输出的不仅是器物,更是中国人的智慧和生活方式。在宋元时期,这里集中了独步天下的顶级制造技术,被后人称为当时的“硅谷”。今天的龙泉,依然有“夺得千峰翠色来”的神姿,依然有“雨过天青云破处”的风华。

杭州国家版本馆的青瓷屏扇开开合合,打开的不仅是版本珍藏的宝库,也是传承千年的龙泉青瓷的无限可能性。

By Zhu Dawen Tu Jiayu

Stepping into the south gate of the Hangzhou branch of the China National Archives of Publications and Culture, you will be greeted by impressively large plum-green screen doors.The fine and smooth green doors stream down like distant mountains and limpid water. A total of 251 screen doors are installed here, comprising 70,000 hand-fired celadon panels, all from Longquan kilns in Zhejiang. Throughout the entire history of celadon craftsmanship, it is extremely rare to find such a largescale application. Coming from everyday utensils to a grand architecture, from mundane scenes to a heritage project, ancient Longquan celadon has made a glorious comeback at this latest cultural landmark of Zhejiang.

The other day, we made a special trip to Longquan and talked to Jin Yirui, the inheritor of the intangible cultural heritage of Longquan celadon craftsmanship, who shared with us challenges and inspiration as well as cultural inheritance and innovation during the process. The Southern Song Dynasty Ge Ware Co.,Ltd. that Jin founded is one of the three celadon screen-door manufacturers for Hangzhou branch of the China National Archives of Publications and Culture.

The celadon screen doors are made with a new dedicated type of kilns. Jin’s company established three such new kilns, which had been firing day and night to produce 10,000 celadon panels since last April. It all started with a meeting in July 2020. A group of people from Hangzhou was recruiting enterprises in Longquan for a major project, which was to make large 30cm x 80cm celadon panels. The 20-odd key local manufacturers attending the meeting all considered the mission impossible. The required surface flatness of celadon panels was way different from that of ordinary porcelain products. A flat and flawless celadon panel was almost unattainable by non-machine cutting. Yet Jin kept contemplating possibilities after the meeting. “To innovate is to break through a certain limit in previous technology.” There is no shortcut on the road to innovation. Jin started research and trial firing repeatedly.

Six months later, the resultant celadon panels gradually expanded from a small size of 15cm x 30cm to the largest size that a kiln could accommodate at that time — 30cm x 60cm.By then, the companies had withdrawn one by one. Only Jin’s company and other two entered the final production process. Jin realized that to further break through the limit of size, large new equipment must be tailored for large panels. The new kilns, which he had managed to create, brought other problems. Inside the kiln,when 20 layers of partition boards were fully loaded, the entire furnace increased its usual weight by about twice, causing potential load-bearing risks. Jin had to redesign the track of the kiln car and reinforce the base with iron pieces. Besides, with celadon panels densely spaced, cooling was not fast enough. Jin then made several ventilation holes on the side and front of the kiln. In over a year’s time, Jin Yirui rejected all the other orders. When the first largescale celadon panel came out successfully, he couldn’t help crying.

金逸瑞制作青瓷器。金逸瑞/供图Jin Yirui works on a piece of celadon ware. Photo credit: Jin Yirui.

金逸瑞。Jin Yirui.

金逸瑞哥窑作品《母子莲》。金逸瑞/供图Mother and Child Lotus, a piece of celadon ware by Jin Yirui. Photo credit: Jin Yirui.

Green is the color of mountainous and riverine landscapes.Longquan kilns, seated in Longquan county between mountains and at the source of the Oujiang River, boast the longest history in Chinese porcelain making — about 1600 years. Jin is captivated by this greenness. When he learnt that the products would be used as the main components of the Hangzhou branch of the China National Archives of Publications and Culture, he felt a certain inevitability of destiny, or plum-green, represents “the pinnacle of celadon glaze color and texture”, which, conveying an aesthetic atmosphere where green plums hanging on the branch fresh and verdant, exactly corresponds to the Chinese character“Run” (gentle and smooth) in this place, which is also known as the Wenrun Pavilion. However, when a twice- fired panel was cut and trimmed, edges of its white base would be exposed on all sides,which would inevitably damage the overall beauty of the screen door when viewed from the side. Therefore, the traditional firing procedure was amended, where panels would be fired three times so the thin edge of one-centimeter width could also be covered with the delicate plum-green glaze. Jin hopes that in a hundred years, every celadon panel can still be a vintage artifact when dismantled. This obsession is rooted in the revival of Longquan celadon since the 1950s. At that time, with the support of the central government, Longquan kilns were rekindled. The newly established Longquan State-owned Shangyang Porcelain Factory brought together many masters of celadon art, including Xu Chaoxing, the then inheritor of Longquan celadon craftsmanship.Jin Yirui’s family also caught up with this wave. Now, of his six siblings, five them are engaged in the industry. In 2007, Jin Yirui officially apprenticed himself to Master Xu Chaoxing. Two years later, the traditional firing techniques of Longquan celadon became “human intangible cultural heritage”. The baton of the art was passed to Jin’s generation.

One more firing adds 15 hours to the finish time. Besides,during the third firing, glazing became increasingly difficult, and the glaze easy to crack. “The final yield is only 50 percent,” Jin said sadly. Yet this kind of desperate approach was chosen for the perfection of details. During the construction of the Wenrun Pavilion, Jin Yirui came to Hangzhou once. When he saw the carefully toned celadon panels that he had caressed day and night so grandly laid out, his excitement and pride were beyond words,“Celadon is finally used as a main construction component,10,000 square meters in all!”

“In porcelain hides the most profound culture.” Reluctant to throw away the “defective panels” in the trial firing, Jin stored all of them in his studio, totaling nearly 10,000 pieces.

Back in the Southern Song dynasty (1127-1279), celadon ware was used as flower vases, tea cups, and incense burners, which embodied the life aesthetics of Song people: “From splendid blaze,they returned to the common.” The celadon screen doors convey a strong sense of cultural self-confidence. In Jin’s view, the grand size, thrice firing and large-format layout are major innovations of the project, which have not only pushed the artistic achievements of Longquan celadon to a new peak, but opened a door for its future development.

Jin Yirui and his colleagues spend more time exploring the humanistic connotation of Longquan celadon that connects the ancient with the modern. “With the whole piece of celadon open for use, it’s just a question of how to use it.” Picking up a panel, Jin said, “Traditional artifacts are classic, though people of different generations have different understandings of it”. If this form of celadon ware can be generally accepted, the entire Longquan celadon industry will see a “new creative space and independent market with no upper limit”. Jin made various attempts to cut defective panels into different shapes of tea trays, pot and cup holders. He also treasured a complete piece of glaze that was accidentally peeled off during firing for future creative use. Against the wall of his studio leant a giant celadon board whose height is comparable to that of a person, or four times the size of a panel as used at the Hangzhou branch of the China National Archives of Publications and Culture, which is his proud work of challenging the limits. Flames of creative enthusiasm are always flaring in this celadon master.

猜你喜欢 窑炉龙泉青瓷 六朝青瓷工艺的革新与影响华人时刊(2022年9期)2022-09-06夺得千峰翠色来——王玮的青瓷艺术金桥(2022年7期)2022-07-22龙泉青瓷摄影与摄像(2020年4期)2020-09-10河南荥阳市一碳素厂窑炉坍塌 致3人死亡3人受伤消防界(2019年9期)2019-09-10行业首条“负离子生态石”宽体窑在恩平点火佛山陶瓷(2018年2期)2018-03-10科达承建561 m最长抛釉砖窑炉顺利投产佛山陶瓷(2017年3期)2017-04-06关于窑炉节能的答疑佛山陶瓷(2017年1期)2017-02-23幸福龙泉昆嵛(2016年3期)2016-09-23在龙泉,有一种温度叫暖心昆嵛(2016年3期)2016-09-23龙泉汤昆嵛(2016年3期)2016-09-23本文来源:http://www.zhangdahai.com/shiyongfanwen/qitafanwen/2023/0411/582635.html