【www.zhangdahai.com--其他范文】

ZHOU Yi-jing, LUO Jin-rong, SHAO Yan-yan, XIA Zhou, SHAO Yuan-long,2,3,*

(1. College of Energy, Soochow Institute for Energy and Materials Innovations (SIEMIS), Key Laboratory of Advanced Carbon Materials and Wearable Energy Technologies, Soochow University, Suzhou 215006, China;2. School of Materials Science and Engineering, Peking University, Beijing 100871, China;3. Beijing Graphene Institute (BGI), Beijing 100095, China)

Abstract:

Along with the emergence of wearable electronic devices, green energy devices like Zn-ion hybrid supercapacitors(ZHSCs), which are extremely safe and cheap, and have excellent stability and high power energy densities, have received great attention. Carbonenes, mainly including graphene and carbon nanotubes (CNTs), are promising materials for ZHSCs because of their exceptional electrical conductivity and excellent mechanical stability. A comprehensive overview of strategies for the modification of carbonene-based materials for ZHSCs, and a brief summary of their energy storage mechanisms is given and topics for potential research are suggested.

Key words: Zn-ion hybrid supercapacitors;

Carbonene materials;

Carbon nanotubes;

Graphene

In recent years, given that it can be employed for diverse purposes, containing healthcare, entertainment, and so on, wearable technologies have attracted extensive attention from academia and industry[1-5].The emergence of these industries facilitates the development of high-performance energy storage devices which features low expense and prominent electrochemical properties[6-8]. Unlike the perilous lithium-ion energy storage systems with organic electrolytes, Zn-based electrochemical systems (e.g., Znion batteries, ZHSCs) have become the promising candidates for the next generation of electrochemical energy supply equipment resulted from their excellent properties and environmental friendly[9-12].Among them, in combination of complementary advantages between batteries and supercapacitors, ZHSCs stand out due to their rapid electrochemical reaction process and favorable energy density[11-16].

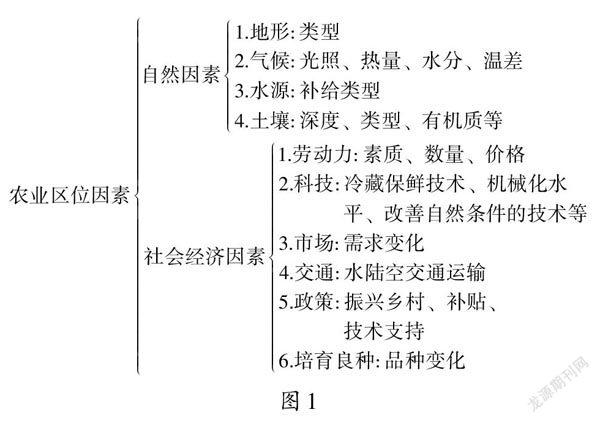

Generally speaking, ZHSCs are comprised of a capacitor-type cathode, electrolyte and a battery-type anode which is typically a zinc anode. Carbon materials have drawn considerable attention in ZHSCs as a result of their main characteristics of large specific surface area (SSA), favorable electrical conductivity,excellent chemical stability, low cost, and tunable structure of nanopores[17-20]. Therefore, they are widely used for cathode materials, such as porous carbons (PC)[21-24], hollow carbon spheres (HCS)[12,25,26],graphene-based materials[15,27,28]and carbon nanotubes (CNTs)[14,29,30],etc.(Fig. 1). Nevertheless, the capacity of carbon-based materials at present shows mismatch with the inherent theoretical capacity of zinc electrodes (823 mAh·g-1), so that the electrochemical performance of ZHSCs fail to meet the expectation. To date, researches on ZHSCs cardinally focus on developing high-capacity cathodes and regulating electrolytes characteristics. Despite a breakthrough, plenty of troubles still require us to overcome. To promote a deeper comprehending of energy storage mechanism in ZHSCs and provide insights for promising strategies to improve the electrochemical performance, there is a great deal of exploration waiting for us to do.

In this review, we first concentrate on the energy storage mechanism of ZHSCs, and then elaborate the advancement of carbonene materials (i.e., CNTs and graphene), which possess excellent chemical and mechanical stability. Subsequently, we evaluate the influences of zinc anode as well as electrolyte on ameliorating performances of ZHSCs. Ultimately, we express the perspective with respect to existing difficulties and prospects in practical applications of ZHSCs.

In ZHSCs, the electrochemical charge generally storedviarepeated ion adsorption/desorption on the surface of porous carbon which enables ZHSCs with rapid reaction processes[11].

It is generally accepted that zinc anode is responsible for a fast plating/stripping process of Zn2+(Eq. 1).

The working mechanism of the carbon electrodes is more complex compared with the zinc anode.First of all, the type of ions that participated in physical adsorption process is ambiguous. Some researches suggested that cations are involved in the adsorption of carbon surface instead of anions (Eq. 2)[33,34], while others suggest that it is the anions (Eq. 3)[26,35].Secondly, some studies held the opinion that there are not only physical adsorption of electrolyte anions on the carbon cathode surface, but also possible chemisorption of electrolyte cations on/near the carbon cathode surface for redox reactions (Eq. 4,5)[14,23,35,36],which provides additional pseudocapacitance. Some researches insisted that the fundamental energy storage route in the step of discharge is the physical adsorption of X-(anion in the electrolyte) on carbon cathode. Besides, the extra pesudocapacitance is provided by the chemical adsorption of H+and Zn2+combined with C-O bonds. While other studies suggested that C-OH dominates reversibly this chemical reaction in the proceeding of discharging/charging processes. Namely, C-OH bound firmly with Zn2+by chemical bonding, thereby forming C-O-Zn bond.Moreover, it was found that doping heteroatoms to carbon materials could enable enhanced electrochemical performance. Zhaoet al.believed that the doped O atom can provide more active sites for the pseudocapacitance[35]. Lu and Zhaoet al.agreed that the chemical adsorption between the zinc ion and the carbon surface is also promoted when the heteroatom N is introduced[23,35]. In general, the introduced O is served as active site to produce pseudocapacitance,while doped N atom profoundly enhances the conductivity of electrodes, thus increasing the ion adsorption/desorption efficiency.

Simultaneously, there are a series of completely irreversible precipitation/dissolution process on the carbon cathode (Eq. 6). Furthermore, Kang and Zhaoet al.suggested that the precipitation/dissolution reactions of Zn4SO4(OH)6·xH2O are influenced by the pH of electrolyte[11,35]. Along with continuous water decomposition, concentration of OH-located around electrode interface increases evidently, subsequently forming zinc hydroxysulfate Zn4SO4(OH)6·xH2O due to strong interaction among Zn2+, OH-and SO42-, thus contributing additional capacity which involves the deposition/dissolution of Zn4SO4(OH)6·xH2O. Nevertheless, its contribution to capacity is limited. If there are sizable amounts of OH-, the formation of ZnO and zinc dendrite will be initiated by the resultant Zn(OH)42-during Zn deposition process. Furthermore massive by-products of Zn4SO4(OH)6·xH2O will stack irregularly on carbon electrode, resulting in an inferior Zn reversibility.

Further researches are needed to elucidate the energy storage mechanism of ZHSCs. The identification of in-depth understanding of the storage mechanism contributes to improving the design of electrode materials. Therefore, the corresponding electrochemical performance is thus enhanced.

Carbonene materials are low-dimensional carbon materials with sp2hybridization of carbon atoms,mainly including graphene and carbon nanotubes[37].The great electrical conductivity and porosity possessed by carbonene materials (CNTs and graphene)enable them to be high-performance capacitive electrode materials[38].

3.1 CNT-based materials

In 1991, Iijima reported that a type of needle-like carbon, now called CNTs, having attracted considerable attention[39]. Single walled carbon nanotubes(SWNTs) are formed by wrapping a single graphene sheet into a cylindrical shape, while multi-walled carbon nanotubes (MWNTs) are arrayed in the structure of graphene coaxial tubes around the core of SWNT[40]. Benefited from outstanding properties including large SSA and superior electrical conductivity, CNTs served as promising electrode materials for electrochemical devices have been universally investigated[41-43](Table 1).

3.1.1 CNTs electrodes

Wanget al.prepared the oxidized carbon nanotubes (oCNTs) by improved Hummer’s method,which was further utilized as the cathode to fabricate the ZHSCs firstly[44]. Research results revealed that asassembled oCNTs//Zn ZHSCs achieved a higher capacitive contribution compared with pure CNT//Zn ZHSCs. Besides, they tested the oCNTs performance in the same pH value of ZnSO4and H2SO4solution separately, and found that the capacitive behavior of oCNTs in H2SO4solution is inferior to ZnSO4, thus indicating that zinc ion can provide higher capacitance. Two reasons were proposed for the enhanced electrochemical performance of oCNTs than conventional CNTs. On the one hand, the oxygen modified oCNTs have a larger SSA (211 m2·g-1) than original CNTs (120 m2·g-1) which contributes more ions storage sites. On the other hand, the oxygens on the surface of the oCNTs provide additional pseudocapacitance involving Faradaic processes. As a result, the ZHSCs exhibited an exceptional capacity of 20 mF·cm-2and demonstrated a consistent cycle life up to 5 000 cycles. As shown in Fig. 2a and b, Quet al.developed anin situelectroplating anode, in which CNTs paper is served as the working and counter electrodes, respectively[14]. The CNTs micro-electrodes are played the part of working and counter electrode during Zn electroplating process, respectively, and ZnSO4solution was utilized as electrolyte.Consequently, the deposited Zn was obtained by the reduction of zinc ions in the electrolyte. Anodes with different Zn content of zinc-ion micro-supercapacitors (ZmSCs) can be derived by altering electroplating times. This strategy allowed replenishment of zinc anode without destroying the zinc structure, effectively inhibiting the capacity decline brought by the formation of Zn dendrite and dead Zn. As a result, the asprepared device enables an excellent area capacity of 83.2 mF·cm-2at 1 mA·cm-2, further demonstrating an area capacitance of 60.9 mF·cm-2, which is equivalent to 87.4% retention at 5 mA·cm-2after 6 000cycles. Meanwhile, it also shows excellent flexibility,revealing promising prospects in miniaturized electronics industry and flexible devices. Guanet al.fabricated a three-dimensional (3D) nitrogen-doped CNT@CNT (N-CNT@CNT) fiber electrode (Fig. 2c,2d)[29]. Benefiting from the porous architecture with a large SSA, this cathode can supply massive reaction active sites for the ion adsorption, as well as curtailing the distances of electrolyte ions migration to facilitate the reaction dynamics. The prepared fiber-shaped zinc-ion hybrid supercapacitor (FZHSC) can realize an exceptional areal capacitance of 11.52 mF·cm-2with a current density 0.71 mA·cm-2. More attractively, the doped N atoms can accelerate the ion/electron transfer within 3D N-CNT network, thus enhancing the whole electrochemical properties. The FZHSC retains 88.5% of its initial capacity commendably after cycled for 10 000 at 1.42 mA·cm-2. Additionally,the FZHSC features in excellent electrochemical stability which can be attributed to stable structures and excellent mechanical performances, establishing a fine foundation for its development in wearable field.

Though CNTs used as the cathode materials for ZHSCs have shown extended cycling stability and promising applications in flexible devices, we can still further enhance its electrochemical performance for more practical applications by introducing active groups on its surface and increasing the SSA.

3.1.2 Combined with electrode materials

However, CNTs used as the cathode materials exhibit low capacity. In general, CNTs are commonly compounded with other electrode materials to enhance the electrical conductivity of original electrode,cycling stability or flexibility. For example, Maet al.combined sufficient electrical conductivity of CNTs with high theoretical capacity of MnO2to investigate the influence of weight ratio and the corresponding electrochemical properties in ZHSCs[45]. The results showed that the capacity of MnO2-CNTs cathode was positively correlated with the content of MnO2.Lately, Mahanandia’s group synthesized activated carbon (AC)/MWNT@ZnFe2O4(ZFO) composites(Fig. 3a, 3b)[46]. Calculated from cyclic voltammetry(CV) measurement (Fig. 3c), the presence of highly conductive MWNTs probably accelerated the transference of ions, thereby generating large capacitance with the highest specific capacitance of 613 F·g-1at 5 mV·s-1, higher than AC (357 F·g-1), MWNTs(284 F·g-1) and ZFO (329 F·g-1). The addition of CNTs not only improves conductivity, but also prevents MXene from self-stacking. Songet al.obtained CNTs delaminated V2C MXene (DV2C) with unique cross-stacking structure (Fig. 3d)[30]. Owing to the networks of CNTs, the as-prepared films displayed the improved conductivity and dynamic behavior. In particular, it’s believed that the energy storage may be promoted and the self-restacking of delaminated V2C MXene can be prevented, resulted from intense van der Waals interactions occurred from layer to layer.The laminated MXene exhibited a remarkable capacitiance of 190.2 F·g-1at the current density of 0.5 A·g-1on account of the excellent conductive skeletons benefited from composed CNTs, as well as superior cyclic stability (Fig. 3e), implying excellent rate performance and durability.

Recently, some compounded CNTs by graphenebased materials have also received considerable attention. Lately, Chenet al.fabricated ZHSCs with reduced graphene oxide/CNTs (rGO/CNTs) fiber cathode (Fig. 4a)[28]. Similarly, the addition of CNTs boosts the electron transfer as well as discouraging the compact stacking of the rGO nanosheets. Experimental results revealed specific surface of rGO/CNTs with mesopores was higher (265 m2·g-1) than that of rGO fibers (24 m2·g-1), furnishing a considerable active sites for ion adsorption/desorption. In this regard, the as-prepared quasi-solid state ZHSCs exhibited a high volumetric properties of 104.5 F·cm-3. The assembled fiber-shaped ZHSCs held a prominent volumetric energy density of 48.5 mWh·cm-3along with the power density of 179.9 mW·cm-3, which endows it to possess the best performance for energy storage among all fiber-shaped ZHSCs reported before (Fig. 4c). Furthermore, they carried out the CV measurements of the device at different bending angles, such as 0°, 45°,90° and 120° (Fig. 4b), demonstrating its excellent flexibility. In addition to the merit of reducing from stacking, the incorporation for MWNTs can also provide remarkable mechanical strength. Huang and co-authors fabricated ZHSCs based on MWNTs-rGO composited fibers[47]. As displayed by Fig. 4d and 4e,the MWNTs-rGO fibres were not in damage, even in the circumstance of winded or knotted state. The fiber-shaped ZHSCs device demonstrates superior flexibility (Fig. 4f) and presents superb capacitance retention of 87.8% based on its initial capacitance in the condition of bending at 150°. Utilizing the highly conductive, flexible and stretchable features of CNTs,Limet al.fabricated a conductive textile, CNT-rGOfabric composite (CNT-rGO@F), for wearable application (Fig. 4i)[48]. It is noteworthy that CNT-rGO@F surpassed most of former friable graphene-based electrodes, maintaining 90.0% capacity retention even exerting 50% tensile strain (Fig. 4h). Fig. 4g displays the CV curves of the supercapacitor cycled in stretching repeatedly at 50% strain. Evidently, the capacitance of the device is maintained at 90.4% with 1 000 stretching cycles compared with the first stretching cycle. Its stretchable properties hold great promise for wearable device applications.

In addition to the advantages mentioned above,CNTs can reduce the generation of zinc dendrites to stabilize the Zn anode as well. Wanget al.reported that CNTs was utilized as a polyfunctional separator/interlayer to suppress dendrite growth of Zn electrode[49]. The porous frameworks adhered to the zinc anode automatically modulates Zn2+deposition behavior. Besides, the conductive CNTs frameworks contributed to a homogeneous electric field to sleek Zn deposition, thereby impeding the generation of zinc dendrites and corresponding parasitic reactions.The as-prepared device demonstrated ultralong lifespan with 7 000 cycles at 2 A·g-1. Lately, Sunet al.plated Zn nanoflakes onto 3D-printed CNTs skeletons through distinctive electroplating measure to suppress dendritic formation[50].

Above all, CNTs have been used to increase conductivity, prevent self-stacking, stabilize zinc anodes and enhance electrochemical stability,etc.On account of its stretchability, superior electrochemical properties and excellent conductivity, CNTs provide a prospective pathway for devising novel durable ZHSCs devices with high safety, stability, and capacity.

3.2 Graphene-based materials

Graphene refers to a two-dimensional (2D)hexagonal honeycomb lattice of carbon atoms crowded firmly together, as well as serving as the fundamental constructing units for varied dimensional graphite-based materials[51]. Graphene enjoys high electrical conductivity, large SSA (2 630 m2·g-1)[52-54],superb intrinsic mobility (200 000 cm2·V-1·s-1)[55,56],and strong mechanical property[57-59], which make it popularly applied in ZHSCs. Monoatomic thick graphene layers with two-dimensional planar geometry can be employed as more efficient materials in electrochemical fields compared to CNTs[38](Table 2).

Table 2 Electrochemical performance summary of graphene-based materials for ZHSCs.

3.2.1 Structure design

In 2019, Zhanget al.systematically reported the achievements of graphene-based materials which worked as cathodes for ZHSCs[15]. Detailedly, they fabricated the ZHSCs through activated microwaveexfoliated graphene oxide (aMEGO) with zinc slab,thus balancing energy density and cycling life commendablyviataking advantage of 3 mol L-1Zn(CF3SO3)2electrolyte which could enable excellent Zn reversibility. The aMEGO//Zn exhibited an extremely long cycling lifespan with 93% retention of the capacity after 80 000 cycles and displayed a ultrahigh gravimetric energy density of 106.3 Wh·kg-1with a power density of 31.4 kW·kg-1.

Recently, the works on the structural design of graphene-based materials have gained extensive attention. As a result of irreversible π-π stacking and electrostatic interactions between graphene layers,graphene layers are prone to attract mutually and restack compactly, which usually lead to inefficient charge storage, reducing the feasibility of large-scale development of graphene materials in energy storage electrodes, composites,etc.[22,60]. Furthermore, Jiaet al.utilized the expandability of graphene oxide (GO)films to assemble Graphene hydrogel (GH) films innovatively, and serve it as cathode for ZHSCs[61]. The interaction forces of pretreated GO films such as van der Waals, hydrogen bond and so on, could be regulated by reaction time of hydrothermal procedure, thus achieving variable expansion degree of p-GO films(Fig. 5a). The cross-section morphology of GH-films features in loosely 2D stacked and porous which facilitates the ion diffusion and adsorption behavior(Fig. 5c). As a result, as-fabricated ZHSCs assembled from GH film, shows an unprecedented specific capacity of 99.3 mAh·g-1at current density of 0.2 A·g-1,and presents 90% retention of capacity over 10 000 cycles. More impressively, compared to initial state,no apparent voltage drop appears in galvanostatic charge-discharge (GCD) plots after 10 000thcycles(inset in Fig. 5b), verifying the superior durability and stability of thus-assembled devices. Meanwhile, it rendered a distinctive energy density of 76.2 Wh·kg-1.Apart from carbonene-based materials, organic molecules could also be introduced in the graphene sheets to suppress the aggregation. For example, Huet al.reported a kind of rGO films which is modified with p-phenylenediamine (PPD) molecule. This rGO films were prepared through convenient hydrothermal reduction process, where PPD served as reducing and modified agent[62]. The PPD molecule can be used as an insertion layer to expand the distances between graphene layers, thus creating more channels for electrolyte ion getting access to electrode, enhancing the capacitve energy storage characteristics. Besides, the effective connection between PPD molecules and rGO functional groups could contribute to extra pseudocapacitance. Impressively, the modification of rGO films which is profited from acylation reaction and ring-opening polymerization abates the dispersion pf PPD, yet elevating conductivity caused by partial reduction of amino groups, along with excellent wettability. The ZHSCs composited by the PPD functionalized rGO film with Zn metal renders outstanding areal capacitance of 3 012.5 mF·cm-2, corresponding to an energy density of 1.1 mWh·cm-2. Likewise, Pattananuwat’s group developed a novel cathode through introducing polypyrrole (PPy) nanoparticles to cover Ndoped reduced rGO (N-rGO)[63]. The existence of PPy nanomaterials between rGO layers prevents re-stacking of N-rGO at the interface layers. Wanget al.grew phenanthraquinone (PQ) on GO layers by self-fabrication method in solvents considered of high redox activity of PQ molecule, thus obtaining the graphene hydrogel (GH) morphology with fluffy structures[27].The ultrathin adsorption layer of PQ at the interface and the expanded structure of PQ-GH gave full play to the advantages of PQ electrode such as rapid transport dynamics (Fig. 5d). They also proposed that PQGH offers promising advantages for high performance ZHSCs. PQ-GHs enabled superior properties of energy storage even at ultrahigh mass loading of approximately 11.4 mg·cm-2. In conclusion, this ZHSCs gained a quality energy density of 1.31 mWh·cm-2at 0.81 mW·cm-2, possessing great potential for practical application. On the other hand, Shao’s group tuned graphene film layer spacing by altering the proportion of NHG (hydrazine hydrate thermal reduction of GO)to GO (Fig. 5e)[64]. Through further research, they found that rGO film mixed with 75% NHG in ZnCl2solution displayed unprecedented capacitive properties such as fast kinetics and superior rate performances. The assembled electrode presented a breathtaking cycling life which retained 93.9% of its initial capacity after 100 000 long-term cycles.

In addition, 3D porous structures are attracting attention for their excellent reaction kinetics and transfer capabilities[65,66]. Zhanget al.prepared dense 3D graphene (DGH) by hydrothermal reaction, which possesses a SSA of 208.29 m2·g-1and an outstanding pore volume of 1.50 g·cm-3[67]. The SEM image of 3D graphene hydrogel after hydrothermal treatment displayed the 3D interconnected porous architecture comprising rGO sheets (Fig. 6a). Based on abundant ion transport pathways as well as abundant active sites, the rGO hydrogel//Zn ZHSCs exhibit an extremely high volumetric properties of 118 Wh·L-1at an excellent power capacity of 24 kW·L-1, further demonstrating an ultralong cycle lifespan, retaining 80% capacity after 30 000 cycles at 10 A·g-1(Fig. 6b). Moreover, Fig. 6c shows superior performance of ZHSCs that two ZHSCs coin cells in series can light characters “LZ” consisted of several lightemitting diodes. Subsequently, Yanget al.prepared three-dimensional vertically aligned graphene (3D VAG) by the hydrothermal-assisted unidirectional freezing method[68]. As shown in Fig. 6d, employing anisotropic ice nucleus as precursors transform dispersed GO flakes to cross-linked frameworks with vertically oriented micropores via directional freezing method. Moreover, the structure of the 3D VAG can be manipulated with varied hydrothermal temperature and time (Fig. 6e). Compared with three-dimensional reduced graphene oxide (3D rGO), 3D VAG material exhibited more ion storage spaces, more efficient electrolyte ion diffusion, and better rate performance(Fig. 6f). Due to perpendicular and unrestricted channels, 3D VAG could render rapid reaction dynamics even at high loading mass. The specific capacitance of 3D VAG reached 66.6 F·g-1at a current density of 0.5 A·g-1and the capacitance retention reached 92.2%. The constructed 3D VAG//Zn ZHSCs also showed excellent electrochemical performance. It showed outstanding electrochemical stability with almost no decay of capacity after cycled for 3 000cycles. Moreover, Yanget al.prepared an innovative 3D VAG-polydopamine composite materials as the cathode of ZHSCs[32]. The performance of the compound materials are further elevated which can reach a relatively eminent capacitance of 142.4 F·g-1at the current density of 0.5 A·g-1.

In summary, it’s feasible to introduce guest materials into graphene subjects to solve the stacking problems between graphene layers for the purpose of two-dimensional structural regulation, improve ion transport pathways and increase electrochemically active surface area. Constructing 3D structure of twodimensional graphene flakes to obtain optimal pore size distribution can effectively facilitate the electron and ion transport.

3.2.2 Heteroatom doping

Doping heteroatoms into graphene to enhance electrochemical properties of graphene-based electrode materials has been shown to be an effective measure[69-74]. Liet al.pioneered to adopt doped graphene as cathode for ZHSCs (Fig.7a)[75]. Li’s group developed N, P co-doped graphene (NPG) frameworks, thus reducing the electrostatic attractive forces between graphene layers to prevent agglomeration of graphene. Moreover, the defects and available active sites were improved, providing a favorable structure for subsequent electrochemical performance (Fig. 7b).As expected, the ZHSCs assembled by optimized NPG cathode and Zn metal within 1 mol L-1ZnSO4electrolyte enabled an impressive specific capacitance of 210.2 F·g-1and a wide working voltage of 0-1.8 V.As shown in Fig. 7c, the assembled ZHSCs hold outstanding electrochemical stability that retained approximately 82% capacity cycled for 15 000 cycles under 10 A·g-1. Similarly, Yanet al. achieved NPrGO hydrogelswhere N and P atoms served as heteroatoms based on hydrothermal treatment[31]. They found that pyrrolic-N and pyridinic-N owned excellent effect on ameliorating capacitive properties resulted from decreased band gaps of energy level, which dictates the difficulty of electron transfer, while electronic conductivity and electron transport were significantly facilitated by quaternary-N, thereby enhancing the capacitance and rate performance. In addition, compared with the general carbon, the N/Pdoped carbon materials displays improved surface wettability and widen the working voltage window.Besides, they developed flexible ZHSCs which possessed excellent low-temperature resistance, demonstrating a higher possibility of practical application(Fig. 7d).

Afterwards, Shaoet al.introduced oxygen functional groups to the rGO surface, which exhibit different oxygen functional group contents (Fig. 7e)[76]. In this work, they systematically investigated influences of oxygen-containing functional groups on the charge storage capacity of ZHSCs (Fig. 7f). The adsorption energy barrier of the Zn2+could be decreased by specific oxygen-containing functional groups, subsequently improving its electrochemical charge storage. Nevertheless, the structural defects resulting from several oxygen-containing functional groups could dramatically decrease the superior conductivity caused by the original conjugated structure, which further drastically damaging the Zn2+storage behaviors. Consequently, the momentous determinants of ZHSCs performance are the proper equilibrium of the oxygen-containing functional groups and reduction methods of GO. In combination with density functional theory calculation, this study demonstrated that carboxyl and carbonyl groups have a crucial effect in facilitating chemical adsorption of Zn2+. The ZHSCs with HHT(hydrothermal method with the aid of H2O2)-rGO films have demonstrated a remarkable capacitance of 277 F·g-1and an ultralong lifespan over 20 000 cycles with only 2.2% capacity loss. Quasi-solid-state ZHSCs were developed with great flexibility that this device experienced 0% capacitance decrease with the curvature angle up to 90° under the condition of curvature radius of 1 cm (Fig. 7g).

3.2.3 Combined with electrode materials

Apart from the applications discussed above,graphene-based materials are utilized for other electrode materials as well. For instance, Zenget al.devised MXene-rGO aerogels founded on porous interconnected rGO aerogels matrixes (Fig. 8a and b)[77].As shown in Fig. 8c, it exhibited that the MXene nanoflakes were homogeneously adhered to the rGO flakes. The unique porous framework structure of MXene-rGO aerogels provided superior conductivity and considerable hydrophilicity, and the accumulation of MXene nanoflakes was largely inhibited. Liet al.prepared CoxNi2-xP/rGO as cathode material[78]. Benefiting from the promising characteristics, including excellent electrical conductivity, favorable toughness,and superb SSA, graphene with laminated structures was chosen as the matrix material in this work. Caoet al.electrochemical co-deposited electrochemical exfoliated GO (EGO) and polypyrrole (PPy), thus forming porous compound electrode as cathode of ZHSCs(Fig. 8d and e)[79]. The EGO flakes rendered conductive frameworks which further enhances the rate capability of PPy/EGO electrodes with the conjugated structure of PPy. In contrast, the PPy/EGO-1200 s electrode shows a proved area capacitance of 160.3 mF·cm-2at the current density of 0.5 mA·cm-2which is approximately twice as much as counterparts of pure PPy-1200 s electrode (Fig. 8f). Compared to PPy, the augmented properties of PPy/EGO compound are resulted from interconnected porous structure of the composite electrode and the complex conductive skeletons of the compounds. The long-term durability of ZHSCs with the PPy/EGO composite electrode (81% retention of original capacity after 5 000 cycles) was significantly better than that of the Zn-PPy systems investigated previously. They proposed that the superb cycling life may be due to the extra mechanical backup granted by the EGO networks. Besides, the volumetric changes during ion adsorption/desorption process will be suppressed by the porous morphology of the PPy/EGO and the interactions between EGO and PPy, such as hydrogen bonding and π-π interaction.

4.1 Electrolytes

Aqueous electrolytes are often used in ZHSCs due to the cheap price and excellent security, such as ZnSO4, ZnCl2, Zn(NO3)2, Zn(CF3SO3)2and Zn(CH3COO)2[15,34,80-83]. However, Zn2+is prone to form [Zn(H2O)6]2+in aqueous solution, dramatically enlarging the diameter of Zn2+( Zn2+0.148 nm,[Zn(H2O)6]2+0.86 nm), which may decrease the energy storage capacity. Zhanget al.investigated the Zn stripping/plating performance in varieties of aqueous electrolytes containing Zn2+[15]. It was implied through experiments that ZnSO4and Zn(NO3)2solutions showed inferior coulombic efficiency (CE), which could be traced to plating of irregular Zn and the generation of electrical insulated by-products. Experimental results showed that the concentration of various electrolytes has an influence on Zn plating/stripping CE. Moreover, the acting force between Zn2+and H2O is attenuated, which is ascribed to H2O molecules and CF3SO3-anion firmly, thereby inhibiting the H2O decomposition and corresponding side reactions. Consequently, Zn(CF3SO3)2electrolyte rendered excellent average CE of 98.9% over 1 000 cycles,which promoted the further research on interactions in Zn(CF3SO3)2systems. Chenet al.revealed the crucial role of ZnCl2based electrolytes in ZHSCs[84]. The test results not only suggested that the ability to facilitated ion transport of ZnCl2electrolyte was more capable than other Zn-based electrolytes mentioned above, but also demonstrated that the sequence of Zn2+diffusion capability is ZnCl2> Zn(CF3SO3)2> ZnSO4>Zn(CH3COO)2> Zn(NO3)2. Moreover, they verified that the Cl-ions are indispensable factors for tuning the desolvation behavior of hydrated Zn ion. It has been shown that the [ZnCl]+(H2O)n-1clusters (n=1-6)are easier to remove H2O than that of corresponding[Zn(H2O)n]2+clusters. Ultimately, the Cl-substituted[ZnCl]+(H2O)n-1(n=1-6) clusters with lesser size effortlessly accessed the micropores of activated carbon,which is conducive to elevate spacial charge density of ZHSCs. However, though ZnCl2electrolyte possessed many advantages, the ZnCl2electrolyte had a more severe corrosiveness than ZnSO4electrolyte and exhibited severe polarization when potential reaches approximately 1.4 V[15]. Therefore, researchers prefer to choose ZnSO4electrolyte, which is inexpensive and can operate over a wide voltage window (up to 1.8 V in many works)[11,85]. Furthermore, the Zn(CF3SO3)2electrolyte can effectively decrease amounts of H2O molecules in the sheath of Zn2+. Charge transfer and Zn2+transport cations were thus promoted[86]. As a result, Zn(CF3SO3)2electrolyte is also an attractive choice for researchers. In addition to studying common aqueous electrolytes, it is feasible to introduce electrolyte additives into the electrolyte to regulate ion transport to restrain the formation of Zn dendrites, as used in Zn batteries[87,88].

To develop new application scenarios for ZHSCs, designing new anti-freeze aqueous electrolytes is suggested. The freezing process is an intricate rearrangement from disordered water to ordered ice,which is forced by the formation of additional hydrogen bonds (H-bonds)[89]. Typically, there are 2 strategies have been proposed to suppress the freeze of water by destroying the H-bond networks in the H2O molecules: (1) using highly-concentrated solutions; (2) introducing inhibitor for water freezing.Wanget al.designed ZHSCs with 5.5 mol L-1ZnCl2electrolyte which can work at an ultralow temperature of -60 °C[90]. The concentrated electrolyte suppressed H-bond interaction in water, thus realizing ultralow freezing point. Li’s group demonstrated a hybrid electrolyte which consists of ethylene glycol (EG) and ZnSO4soluion[91]. EG has been extensively utilized as antifreeze in electronic equipments[92]. They well controlled the freezing point through adjusting the EG-towater ratio. The ZHSCs with EG60 (the ratio of EGto-water volume is 60%) can still maintain the extremely superior capacity retention of 50% at -40 °C.In addition, EG40 endows the ZHSCs with ultra-long and steady operation over 110 days at -20 °C. Similarly, Huet al.adopted the ZnSO4/water/EG electrolyte as the electrolyte for ZHSCs[93]. The as-fabricated ZHSCs exhibited remarkable electrochemical performances at low temperatures (even at -40 °C).Moreover, this ZHSCs demonstrated excellent cycle stability even at -20 °C that the capacity retention is up to 97.8% under 0.5 A·g-1after 1 000 cycles.

4.2 Anode

Zinc metal is seen as an ideal material for ZHSCs anode due to its low cost (USD $2 kg-1), excellent gravimetric (5 855 mAh·cm-3) capacity and suitable redox potential (-0.763 Vvs.standard hydrogen electrode)[94-97]. Nevertheless, the Zn surface is subject to side reactions that convert Zn into electrochemically inert "dead" Zn, thus reducing the utilization of Zn, and the zinc anode also suffers from dendrite growth[98]. Wanget al.have an attempt to place CNTs scaffolds between Zn slab and glass fiber separator to hinder the expansion of dendrites and the breeding of by-products, as mentioned in the CNTs part of this paper[49]. Liuet al.also coated carbon materials (mesoporous carbon with hollow spheres, MCHSs) on zinc electrode[26]. The authors claimed that MCHSs coatings can effectively inhibit and control the dendrites growth. The ZHSCs comprised MCHSs-coated Zn showed excellent cycle stability of 100% after 1 000 cycles at 0.1 A·g-1and 96% after 10 000 cycles at the current of 1 A·g-1. Apart from carbon-based materials,owing to the good chemical inactivity of the In layer(-0.338 Vvs.standard hydrogen electrode) and the high hydrogen evolution overpotential, Kanget al.decorated the zinc electrode with In metal layers[99].After the decoration with an In interface layer, the Zn@In||Zn@In symmetrical cell presented a prominent plating/stripping cycling stability over 1 500 h with almost negligible voltage hysteresis at current density of 0.2 mA·cm-2and a capacity of 0.2 mAh·cm-2. Moreover, ZHSCs constitute Zn@In anode and AC cathode achieved a greatly extended durability for about 5 000 cycles, which surpassed bare Zn electrode (failure only after 400 h). Layer decorative zinc surfaces, acting as a both corrosion inhibitor and a nucleation agent, is a simple but effective strategy to inhibit both corrosion and dendrite growth. This work may open up a pioneering avenue for stabilizing Zn anode in rechargeable aqueous energy storage systems.

Additionally, we can also design the structure of the Zn electrode to ameliorate Zn2+transfer characteristic and the whole electrochemical properties of ZHSCs. Chaet al.proposed 2D and hierarchically nanostructured Zn (2D-Zn) as anode of ZHSCs[100]. They realized the tunable target of morphologies and inner space density of 2D-Zn electrodes through electroplating Zn on the porous matrix material with varied potential. The flat-type ZHSCs (2D-Zn anode and AC cathode) achieved a superior energy density of 208 Wh·kg-1along with prominent cycling stability up to 10 000 cycles at 10.0 A·g-1. Besides, Anet al.designed a distinctive Zn anode with embossed and punched structure to elevate the rate performance as well as enable a superior prolonged durability of the ZHSCs[101]. They found that the unique embossed and punched structure facilitates rapid Zn2+transport and homogenize Zn plating on the electrode surface due to larger surface areas originated from abundant pores,thereby obviously optimizing the capacitive properties. More attractively, the ameliorative interfacial wettability assisted by embossed structure can further accelerate charge transfer. The as-assembled ZHSCs not only obtained unprecedented prolonged cycling performance of 90% capacity retention after 10 000 cycles, but also enabled elevated energy density,which is up to 108 Wh·kg-1, along with considerable power density of 450 W·kg-1.

In this review, we highlight the application and development of carbonene-based materials, namely graphene and CNT in ZHSCs along with the storage mechanism and the study of zinc anodes and electrolytes. ZHSCs represent a prospective development for the future, but there are still some issues that need to be addressed: (1) In-depth study of the energy storage mechanism, which is complex and still controversial,needs to be investigated using more advanced characterization and theoretical studies. The more systematic and in-depth our study of the mechanism, the more we can help improve the ZHSCs system to enhance the performance. (2) For the design and improvement of carbonene-based materials. Carbonene-based materials possess the merit of high electrical conductivity and are suitable to be used in ZHSCs. However,the limited porosity and self-stacking of a carbonenebased materials limit their application. In general, heteroatom doping, the addition of guest materials, being designed as 3D structures or being constructed as composite electrodes can improve some electrochemical properties of carbonene-based materials. The exploration of these modification strategies is indispensable requirements for latent applications of carbonenebased materials. (3) Applications of the devices. ZHSCs are encouraged to be used in many application scenarios benefited from their extremely security, cost effectively, and outstanding energy storage characteristics. From what have been discussed above, we hope that we can develop promising applications for ZHSCs devices in the future in the fields of flexibility,stretchability, self-healing, and low temperature resistance.

Acknowledgements

This project was financially supported by National Natural Science Foundation of China (52003188(Y.S.)), Natural Science Foundation of Jiangsu Province (BK20200871 (Y.S.)), Jiangsu innovation and entrepreneurship talent program(JSSCRC2021529), Gusu"s young leading talent(ZXL2021449), Key industry technology innovation project of Suzhou (SYG202108).

本文来源:http://www.zhangdahai.com/shiyongfanwen/qitafanwen/2023/0608/608881.html